PRODUCTS

Ship shore integrated information monitoring system

Ship shore integrated information monitoring system secondary development platform is based on years of deep industry cultivation and widespread application of the product. It is an industry application platform for remote data collection, covering functions such as device access, device management, data storage, data display, data analysis, user management, maintenance work orders, etc.

Key words:

Category:

Product Center

Support hotline:

Ship shore integrated information monitoring system

Graphic details

System structure

The ship's green fuel control, monitoring, and safety system automatically monitors, controls, and alarms the filling and refueling process and fuel supply process of the ship's green fuel, achieving automatic control of the ship's fuel usage process and ensuring the safety of ship operation.

Applicable fuels: green fuels such as natural gas, methanol/ethanol, ammonia, liquefied petroleum gas, and hydrogen.

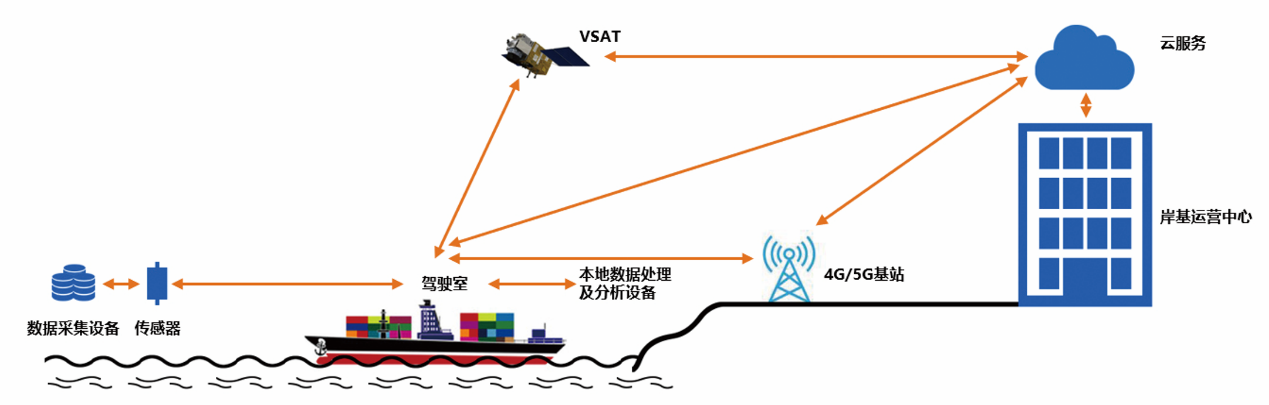

Figure 1 Schematic diagram of the ship shore integrated monitoring system structure

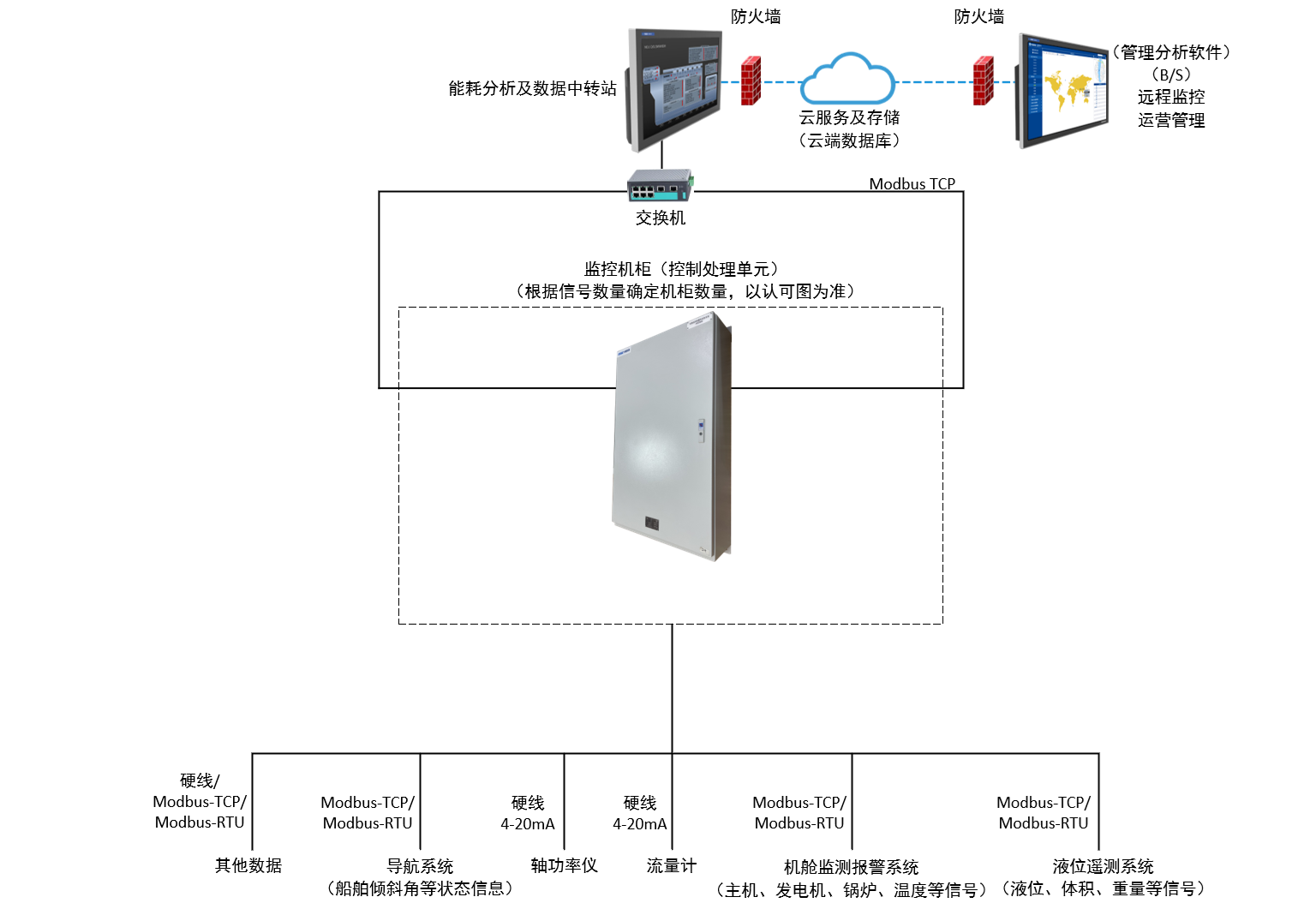

As shown in the following figure, the hardware configuration of the energy consumption and shipping management system mainly includes the driver's cab control panel, central control room control panel, monitoring cabinet, energy consumption analysis and data transfer station, switch, firewall, and on-site instruments and meters (including flow meters, shaft power meters, etc.). The software configuration includes the driver's cab control panel software, central control room control panel software, energy consumption analysis and data transfer software, and shore based remote management analysis software, And PLC controller program. The monitoring cabinet communicates with the cabin monitoring alarm system, liquid level telemetry system, navigation system, and other systems or equipment with data input and output requirements (Modbus TCP/RTU) to collect real-time data from these systems or equipment. At the same time, on-site instruments and meters (shaft power meters, flow meters, etc.) transmit the collected real-time data to the monitoring cabinet through hard wires (4-20mA). The monitoring cabinet calculates and processes the collected real-time data, and transmits it to the energy consumption analysis and data transfer station through Modbus communication (Modbus TCP/RTU). The transfer station stores real-time data, historical data, and logs of the system, and conducts energy consumption and energy consumption analysis, emission analysis, navigation analysis, and navigation suggestions based on the collected data, And push the data to the client software (management analysis software) through ship shore communication (format to be determined) for data analysis and display, and synchronously store these data in the cloud database. The cockpit control panel can set fuel consumption or speed. After setting, the system can adaptively and automatically optimize propulsion power based on real-time collected information such as speed, draft, and sea conditions, and control the output of the optimization results to reduce navigation fuel consumption.

Figure 2 Energy consumption and shipping management system structure diagram (based on the approved diagram)

System composition

- Energy consumption analysis and data transfer station: including 1 maritime computer and 1 maritime display (or maritime all-in-one machine), keyboard, mouse, equipped with 1 switch, and deployment of energy consumption analysis and data processing software. The protection level of the maritime integrated machine and maritime display is IP65 on the front panel and IP22 on the back panel. Can be installed on the driver's console or deployed in other locations;

- Central control room control panel: In the form of a touch screen and physical devices, the physical devices include buttons, indicator lights, buzzers, dimming knobs, etc. The functions of the physical buttons are designed and configured according to the needs of Party A. Touch screen deployment control panel software, which can view relevant alarm information and real-time parameters. The protection level is IP65 for the front panel and IP22 for the back panel;

- Shaft power meter: holding shaft measuring instrument for torque and power measurement. It can be installed on the propeller shaft or connecting shaft, and the model of the shaft power meter can be selected based on the final determined installation position;

- Flowmeter: collection of main engine inlet pipe flow meters (2 sets), shared return pipe flow meters (1 set) for two main engines, auxiliary engine inlet/outlet oil flow meters (2 sets), boiler flow meters (1 set), volumetric flow meters, and installation of oil supply pipelines;

- Marine electronic inclinometer: used to measure the state information of ship inclination angle.

Product function

- Fuel consumption setting: Fuel consumption parameters can be set through the cab control panel and transmitted to the monitoring cabinet through serial communication (Modbus RTU) for propulsion power optimization calculation;

- Speed setting: Speed parameters can be set through the cab control panel, and transmitted to the remote control system control box of the main engine through the monitoring cabinet to indirectly control the speed. And transmit it to the monitoring cabinet through serial communication (Modbus RTU) for propulsion power optimization calculation;

- Automatic optimization of propulsion power based on real-time operating conditions: The monitoring cabinet collects real-time operating conditions parameters such as the host, generator, boiler, and navigation information. Combined with the fuel consumption and speed parameters set by the cab control panel, the controller module program designs an automatic optimization algorithm for propulsion power. Combined with the collected real-time parameters, the optimized propulsion power is output to the propulsion remote control system for real-time control and adjustment of propulsion, Implement automatic control of propulsion power based on real-time operating conditions to reduce fuel consumption during navigation;

- Monitoring, alarm and control: deploy corresponding application software for energy consumption analysis and data transfer stations, cockpit control panels, and centralized control room control panels, display real-time alarms and parameter information monitored by energy consumption and shipping management systems, and have sound and light alarm indication, alarm confirmation, and noise reduction functions;

- Energy consumption analysis: Deploy corresponding application software for energy consumption analysis and data transfer stations to display and store real-time data, historical data, and logs monitored by energy consumption and shipping management systems. At the same time, an energy consumption analysis model is designed based on monitoring signals to analyze real-time energy consumption data and display the analysis results, such as remaining fuel consumption, cumulative fuel consumption in the current month, distribution of fuel consumption (main engine fuel consumption, generator fuel consumption, boiler fuel consumption), average fuel consumption in the past 50 nautical miles, cumulative average fuel consumption per 100 nautical miles, cumulative average cost per 100 nautical miles, and trend display of multi vessel costs, The specific functions shall be subject to the approved drawings and technical specifications;

- Emission analysis and reporting: Communicate with emission monitoring related systems and equipment through communication, or collect real-time data related to emissions through sensors and other methods. Combined with the designed emission analysis and calculation model, analyze and display the emission situation, including the cumulative emissions of the current month, the latest 50 nautical miles emissions, the cumulative average emissions of 100 nautical miles, and the comparison and display of multi vessel emission trends, The specific functions shall be subject to the approved drawings and technical specifications;

- Navigation analysis and report: Based on energy consumption data and analysis results, combined with information such as navigation path, speed, navigation time, route nodes, and road conditions of the navigation system, comprehensive analysis is conducted to analyze navigation efficiency, fuel economy, navigation costs, and display the analysis results to support the shipowner's operation management and decision-making; Ship information display: In the shipping management interface, you can view the information of all ships, display the ship name and IMO information, as well as the number of ships currently working, about to disembark, and remaining positions;

- User Management: Display all sub users managed under the current account in User Management. The account registered and logged in through the mobile phone number is a top-level master account, and the new user is a child account as a subordinate account of the account. The parent account can delete, edit, assign roles, assign trees, and display items under the tree node for child accounts;

- Ship infrastructure management: used to create basic information about ships, including ship names, current grouped ship labels, start and end times of routes, latitude and longitude settings, ship types, ship lengths, and other information;

- Comprehensive management: used for displaying information related to the vessel, including the number of vessels, total number of equipment, number of equipment online and offline, number of users, number of historical alarms, number of maintenance orders, etc;

- Navigation monitoring: Intelligent system software, which adopts a B/S architecture and can be used on devices with webpage browsing function. It can be accessed on both ship and shore ends, and laptops can be accessed through wireless WiFi access to the network on the ship or shore;

- Engine room monitoring: Intelligent engine room is a technical system that utilizes on-site sensors, transmitters, controllers, monitoring software, and other technical means to automatically collect real-time status information and parameters of various systems and equipment in the engine room. Based on computer technology, automatic control technology, and big data processing and analysis technology, it realizes automatic monitoring, evaluation, and decision-making assistance in ship navigation, management, maintenance, and other aspects. As an emerging field in the era of digital and intelligent technology, intelligent engine rooms have become a trend in global ship design and construction, which is related to the upgrading and innovation of the entire ship industry. At present, Japan, South Korea, and many European countries have regarded intelligent engine rooms as a key development area, and have issued multiple guiding strategic documents. They have also launched a series of key technology research projects in areas such as ship intelligent systems, intelligent navigation, shore based remote control, and ship formation navigation, aiming to seize the future highland of intelligent ship technology and gain the development opportunity of the future "unmanned ship" era;

- Energy efficiency monitoring: It can collect instantaneous fuel consumption data of the main engine, auxiliary engine, and boiler, and transmit it to the company's server through a 4G network. The shore based management end can check the fuel consumption of tugboats through the fuel consumption platform.

Performance

|

Performance characteristics |

CPU configuration |

I7, dual core low-power chip, with a main frequency of 1.9GHz or above; |

|

Memory |

DDR3 8G; |

|

|

Operating system |

Windows 10 64 bit Professional Edition; |

|

|

Graphics card |

Integrated graphics card, supporting openGL4.0 or higher, with 128MB of graphics memory; |

|

|

Hard disk storage space |

SSD 512G; |

|

|

|

The front panel is equipped with power supply, dimming buttons, embedded buzzers, and supports power on and self start. |

|

|

Power supply requirements |

Provide one 220V AC and one 24V DC redundant power supply input. |

|

|

Interface |

4 adaptive gigabit network ports with additional fixed mechanism RJ45 connectors, each port has an independent physical address and can be independently configured with IPv4 addresses; |

|

|

4-way USB interface with USBType-A female head with effective fixation method, supporting USB 2.0 or above specifications; |

||

|

One standard DB15 female VGA video output with fixed threaded holes, supporting video output formats such as screen expansion and replication; |

||

|

One RS-232 standard serial port, using a standard DB9 female connector with fixed threaded holes |

||

|

1-way RS-485 serial port, using a screw fixed and pluggable wiring terminal type |

||

|

1 power state output, providing two states: normally open and normally closed |

||

|

1 external dimming signal input port |

||

|

Support expansion of 4-channel or more output isolated serial port expansion modules, support RS-422/485 protocol (each channel can be independently configured through software to choose RS-422 or RS-485) |

||

|

Support the expansion of 2-way adaptive 100Mbps network interface expansion module with additional fixed mechanism RJ45 connector, each network interface has an independent physical address and can be independently configured with IPv4 addresses |

||

|

Display parameters |

The front panel display area adopts a 22 inch (optional 19 inch or 24 inch) LED backlight LCD screen with a resolution of 1920 × 1080, refresh rate support 60Hz; |

|

|

Contrast ratio: ≥ 800:1; |

||

|

Perspective: ≥ ± 85 °; |

||

|

LED backlight, with a maximum brightness of no less than 300 lumens. The backlight brightness is adjustable, ranging from 0 to the brightest, and supports three dimming methods: software, front panel buttons, and external dimming knobs. |

||

|

other |

The protection level of the front panel is IP65, and the rear panel is IP22; |

|

|

full lamination |

||

|

Design a cable fixing mechanism at the wiring point; |

||

|

Passive cooling without fan; |

||

|

Front panel embedded buzzer; |

||

|

Working temperature: -15 ℃ to+55 ℃; |

||

|

Storage temperature: -20 ℃ to+60 ℃; |

||

|

Working and storage humidity: 5-95% (without condensation); |

||

|

Main board three prevention processing; |

||

|

Other environmental adaptability indicators and display indicators meet the requirements of China Classification Society's "Guidelines for Form Approval Testing of Electrical and Electronic Products (2015)" and related modification notifications, IEC-60945, IEC-6228 related standards. |

||

Applications

Suitable for various ships, offshore facilities, and interaction with the engineer station configuration software of the ship automation system secondary development platform.

Previous

Next

The Ship Shore Link System